by Mika Donahue

Mika Donahue is a student in the wood science program at Oregon State University (United States) and the daughter of a family that owns RLD Company, Inc., a provider of independent timber and glulam fabrication. For the IFSA Tree News, Mika wrote a personal account on what it is like to grow up in the family business and how her career choice ties in with the development of the company.

Growing up, my childhood was not so different from other kids. My two older brothers and I loved to play and explore the world around us. Unlike most families though, our parents run a small business that manufactures heavy timber glulam and log structures. So rather than climbing on park playgrounds, days with Dad meant playing in the lumber yard and exploring the giant wood forts of stacked glulam at the plant. We grew up with the perpetual smell of fir and cedar in the air, the sounds of screeching saws and forklift traffic, and the constant sting of splinters from clambering onto giant wood beams. But most importantly, we grew up with a deep appreciation for the forests and the warm beauty that their resources could provide.

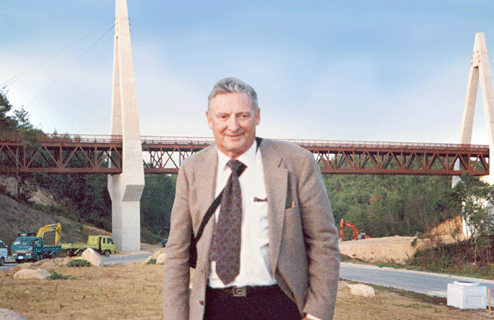

I have always been incredibly proud of the work that my family has put into this unique little business. Founded in 1984 by my grandfather, Robert L. Donahue, RLD Company, Inc. has come a long way. Knowing that this man, who spent his childhood broke and hitching rides on railcars, would eventually use his skills and knowledge gained from the lumber industry to start a small glulam fabrication company, is a constant reminder for me of how much this family has accomplished. Additionally, knowing that the company he started would eventually manufacture the truss system for the world’s longest wood vehicular bridge in Hiroshima, Japan, shows me what RLD Company, Inc. is all about. We are a small business that does big things, and I am consistently blown away by the work that each individual brings to the table.

(Robert L. Donahue, Founder of RLD Company, Inc., standing in front of the Hiroshima Bridge)

After my grandpa retired, my dad has continued to push the company’s boundaries, executing projects that exemplify the structural and aesthetic beauty of wood. Equipped with one engineer, one draftsman, one operations manager and ten or so other machine operators, our team is smaller than most. We currently have an office in Vancouver, Washington, where my parents run the bulk of the operations. There is also a manufacturing facility in Chehalis, Washington, where my two older brothers, Jordan and Garrett, live and work as machine operators and layout crew. We have carved a niche in the engineered wood products industry by being a fully integrated manufacturer that processes raw logs and hardware into a product ready to ship for construction. This allows us the flexibility and versatility needed to manufacture a wide variety of custom projects that range from the long span glulam structure of the Our Lady of Loreto Church in Foxfield, Colorado, to the double curvature art piece of the Lincoln Park Zoo Pavilion in Chicago, Illinois.

(Robert L. Donahue, Founder of RLD Company, Inc., standing in front of the Hiroshima Bridge)

After my grandpa retired, my dad has continued to push the company’s boundaries, executing projects that exemplify the structural and aesthetic beauty of wood. Equipped with one engineer, one draftsman, one operations manager and ten or so other machine operators, our team is smaller than most. We currently have an office in Vancouver, Washington, where my parents run the bulk of the operations. There is also a manufacturing facility in Chehalis, Washington, where my two older brothers, Jordan and Garrett, live and work as machine operators and layout crew. We have carved a niche in the engineered wood products industry by being a fully integrated manufacturer that processes raw logs and hardware into a product ready to ship for construction. This allows us the flexibility and versatility needed to manufacture a wide variety of custom projects that range from the long span glulam structure of the Our Lady of Loreto Church in Foxfield, Colorado, to the double curvature art piece of the Lincoln Park Zoo Pavilion in Chicago, Illinois.

(Picture: Lincoln Park Zoo Pavilion, Nick Ulivieri Photography)

(Picture: Lincoln Park Zoo Pavilion, Nick Ulivieri Photography)

(Picture: Our Lady of Loreto Catholic Church, TomKPhoto)

After graduating from Central Catholic High School in Portland, Oregon, my parents encouraged me to take a gap year and work for the business as bookkeeper and administrative assistant. As a seventeen-year-old girl, helping manage my family’s business accounts and cash flow seemed a little daunting at first, but the experience proved to be more valuable than I could have imagined. Being able to successfully communicate with customers and suppliers while managing important responsibilities for the business gave me a strong sense of independence and real-world application. At times it was extremely stressful. After all, I was just a teenage girl trying to act as professional as possible while interacting with people who have worked in the industry for decades. But, hey, you learn as you go. The industry experience provided me with a much greater appreciation for punctuality and attention to detail than an academic setting could provide. Sure, if you turn an assignment in late you might get a bad grade, but here, if you turn in something late, you can lose thousands of dollars.

With a new perspective, I could more fully appreciate the products and function of our business. However, it wasn’t until I watched a TED Talk from Vancouver-based architect Michael Green regarding the environmental necessity of mass timber building that I really found my spark. Learning about wood’s ability to sequester carbon and mitigate greenhouse gas emissions added a whole new level of importance to my understanding of forestry and wood construction; it has set the stage for my academic pursuits.

Equipped with new inspiration, I headed to Oregon State University to start my Wood Science Management & Marketing degree. The education I received and the network of people I met greatly expanded my scope of the wood industry, and it eventually landed me a summer internship at the Sierra Pacific Industries stud mill. Conveniently located in Chehalis, WA, I was able to live with my brothers and gain experience outside of the family business. Although working with my parents has provided some amazing opportunities for growth and experience, special treatment was inevitable. No matter how much they assured me I was just another employee, I knew I was still their daughter. Working at Sierra Pacific launched me out of my comfy administrative desk job and into a jarring blue-collar work environment with stricter rules and long days of manual labor and machine operation. It was one of the best decisions I’ve ever made and pushed both my mental and physical limits.

After my summer internship, I decided to switch gears and embark on another adventure for a yearlong exchange at the University of British Columbia’s Wood Products Processing program. I am finishing up my last semester here, and the knowledge I have gained from this experience has greatly enhanced my understanding of all aspects of forestry, particularly on a global level.

Currently, my greatest interests still lie in mass timber and engineered wood products. The potential these products can bring to a more sustainable and diverse construction industry places RLD Company, Inc. in an optimal position. It is one of the many reasons I plan to continue working for the family business for the next 5 months. Even though the flexibility I receive from working for my parents doesn’t exactly reflect how things will be in the real world, there are huge benefits for staying involved with the family. The best parts about working for a family business, particularly one as versatile as RLD Company, Inc., are the opportunities to explore all aspects of the business. While I could continue work as a bookkeeper, working for the family business allows me to gain experience with my Dad in project quoting or financial analysis, with our operations manager Davy in scheduling and marketing, or with my brothers in the manufacturing plant learning machine operation and layout. I am always excited to expand my toolbox of knowledge and experience, and I consider myself incredibly lucky to have grown up with such a unique business. Taking part in the manufacturing of heavy timber structures is amazing—structurally and aesthetically, but knowing its importance in the context of the environment and sustainability makes it a passion I wish to pursue for as long as I can.

The author, Mika Donahue, is responsible for the content of this article and can be reached under donahuem(a)oregonstate.edu]]>

(Picture: Our Lady of Loreto Catholic Church, TomKPhoto)

After graduating from Central Catholic High School in Portland, Oregon, my parents encouraged me to take a gap year and work for the business as bookkeeper and administrative assistant. As a seventeen-year-old girl, helping manage my family’s business accounts and cash flow seemed a little daunting at first, but the experience proved to be more valuable than I could have imagined. Being able to successfully communicate with customers and suppliers while managing important responsibilities for the business gave me a strong sense of independence and real-world application. At times it was extremely stressful. After all, I was just a teenage girl trying to act as professional as possible while interacting with people who have worked in the industry for decades. But, hey, you learn as you go. The industry experience provided me with a much greater appreciation for punctuality and attention to detail than an academic setting could provide. Sure, if you turn an assignment in late you might get a bad grade, but here, if you turn in something late, you can lose thousands of dollars.

With a new perspective, I could more fully appreciate the products and function of our business. However, it wasn’t until I watched a TED Talk from Vancouver-based architect Michael Green regarding the environmental necessity of mass timber building that I really found my spark. Learning about wood’s ability to sequester carbon and mitigate greenhouse gas emissions added a whole new level of importance to my understanding of forestry and wood construction; it has set the stage for my academic pursuits.

Equipped with new inspiration, I headed to Oregon State University to start my Wood Science Management & Marketing degree. The education I received and the network of people I met greatly expanded my scope of the wood industry, and it eventually landed me a summer internship at the Sierra Pacific Industries stud mill. Conveniently located in Chehalis, WA, I was able to live with my brothers and gain experience outside of the family business. Although working with my parents has provided some amazing opportunities for growth and experience, special treatment was inevitable. No matter how much they assured me I was just another employee, I knew I was still their daughter. Working at Sierra Pacific launched me out of my comfy administrative desk job and into a jarring blue-collar work environment with stricter rules and long days of manual labor and machine operation. It was one of the best decisions I’ve ever made and pushed both my mental and physical limits.

After my summer internship, I decided to switch gears and embark on another adventure for a yearlong exchange at the University of British Columbia’s Wood Products Processing program. I am finishing up my last semester here, and the knowledge I have gained from this experience has greatly enhanced my understanding of all aspects of forestry, particularly on a global level.

Currently, my greatest interests still lie in mass timber and engineered wood products. The potential these products can bring to a more sustainable and diverse construction industry places RLD Company, Inc. in an optimal position. It is one of the many reasons I plan to continue working for the family business for the next 5 months. Even though the flexibility I receive from working for my parents doesn’t exactly reflect how things will be in the real world, there are huge benefits for staying involved with the family. The best parts about working for a family business, particularly one as versatile as RLD Company, Inc., are the opportunities to explore all aspects of the business. While I could continue work as a bookkeeper, working for the family business allows me to gain experience with my Dad in project quoting or financial analysis, with our operations manager Davy in scheduling and marketing, or with my brothers in the manufacturing plant learning machine operation and layout. I am always excited to expand my toolbox of knowledge and experience, and I consider myself incredibly lucky to have grown up with such a unique business. Taking part in the manufacturing of heavy timber structures is amazing—structurally and aesthetically, but knowing its importance in the context of the environment and sustainability makes it a passion I wish to pursue for as long as I can.

The author, Mika Donahue, is responsible for the content of this article and can be reached under donahuem(a)oregonstate.edu]]>